sensors tracking asphalt cracks

HELLO to a few dozen new people : )

We now have quite a few winners every week :). This week the mystery gift is for 100 people!!

Can 100 of you win???

Want to get featured in the next edition and get the mystery gift?

Let’s get into this week’s game!

Engineering True or False:

Read these three statements and figure out which ones are TRUE:

Statement 1: A 10-story building can sway up to 3 feet during strong winds without any structural damage. TRUE or FALSE?

Statement 2: Adding salt to concrete makes it weaker and causes faster deterioration. TRUE or FALSE?

Statement 3: The Hoover Dam generates enough heat from curing concrete that it would take 125 years to cool naturally, so they built a cooling system with 582 miles of pipe. TRUE or FALSE?

Know which are real?

Want to reach an audience of over 80k engineers? Click here to book a call with me to see how we can partner to help!

What Happened This Week?

1. This "Fingerprint Matrix" Can See Through Walls, Fog, and Your Body

Ultrasound and sonar are useless when there's stuff in the way because waves bounce everywhere creating noise instead of images. It’s kind of like trying to see through fog with a flashlight 🤪

Austrian and French scientists found a hack for this.They scan objects in clear conditions first and record how each one scatters waves (like taking a fingerprint). Then when that same object is hidden behind sand, fog, or human tissue, they blast ultrasonic waves at it.

Most waves scatter chaotically, but some still hit the buried object and carry traces of its fingerprint. Their algorithm compares these messy signals with the stored fingerprint database to pinpoint exactly where the object is.

They tested it with steel balls buried in sand and detecting breast cancer markers that normally disappear in scattered noise.

The really unexpected application? Measuring brain activity through your skull without drilling anything.

I can’t wait to see the wild stuff that comes from this… I LOVE Sci-fi and the future looks epic :)…

2. MIT Discovered We've Been Trying to Fix the Wrong Thing in EV Batteries

For years, scientists thought lithium batteries charged slowly because lithium ions had trouble squeezing into electrode materials. MIT just measured what's actually happening and realized… we've been completely wrong.

They tested 50+ battery combinations and discovered this: when you charge a battery, a lithium ion can't enter the electrode unless an electron transfers at the exact same moment. They're chemically coupled: imagine a nightclub with a strict "you can only enter with a partner" policy.

This happens because the electrode material needs that electron to make room for the lithium ion. Without the electron transfer, the ion just bounces off. The rate of this coupled transfer is what actually controls charging speed, not how fast ions can diffuse like we thought.

Here's why this matters: now that we know the real bottleneck, we can design electrodes that make this electron-ion coupling happen faster. They can also tweak electrolyte chemistry to speed up the process.

It's like spending decades trying to make your car faster by upgrading tires when the real issue was fuel injection. We were optimizing the wrong part. Guess our tesla friends won’t make excuses about needing food so often anymore 😂

3. Roads Will Now Text You Before They Develop Potholes

Roads just suddenly crack and everyone pretends nobody saw it coming. German scientists embedded smart fabric into asphalt so roads can report their own damage before it reaches the surface.

Here's how it works: they weave ultra-thin conductive wires (less than 1mm thick) into flax fiber fabric and bury it in the road's base layer. When traffic drives over the road, it creates tiny internal stresses and micro-cracks. These cracks change how the fabric stretches, which changes its electrical resistance.

Sensors measure these resistance changes continuously. AI analyzes the patterns to predict exactly when and where the road will fail: weeks or months before you see surface potholes.

Current methods either wait for visible damage (way too late) or drill core samples (which damages the road you're trying to check). This fabric just sits there monitoring stress 24/7 like a health tracker.

The fabric is made from cheap renewable flax that's strong enough to survive construction trucks rolling over it. Maybe now they can fix the roads before a supercar owner sues them for a pothole damaging their car?

Your AC Just Got Way Smarter (And It's Going to Save the Planet)

I just found out that every fridge in the world is basically a tiny climate bomb.

Not joking. The refrigerant gas inside your fridge - R134a - has a global warming potential 1,540 times greater than CO2. Every single kilogram that leaks traps as much heat as 1,540 kg of carbon dioxide.

And here's the part that made me put down my coffee: these gases leak during NORMAL OPERATION.

Your AC, your fridge, every heat pump on the planet is slowly bleeding greenhouse gases into the atmosphere right now.

The regulatory nightmare forcing change

The EU signed the Kigali Amendment back in 2016 to phase out these hydrofluorocarbons.

New regulations kick in by 2027, which means manufacturers need to stop using high-GWP refrigerants by the mid-2030s.

Everyone's been scrambling to find alternatives. Propane? It's explosive (A3 flammability rating). CO2? Needs insanely high pressure and costs a fortune. Ammonia? It's literally poisonous and will suffocate you.

The entire HVAC industry has been stuck in this technological dead end.

The shape-shifting metal that changes everything

Exergyn, an Irish company based at Dublin City University, came up with something that sounds like materials science fiction.

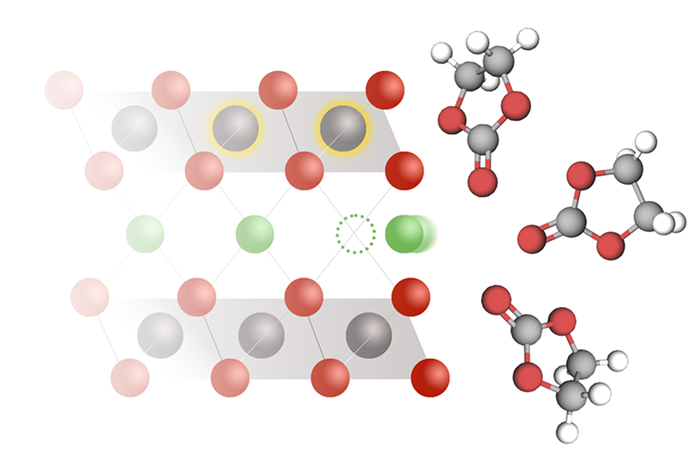

Instead of using gases, they use a shape memory alloy made mostly from nickel and titanium that cycles between two solid states: austenite and martensite.

"We use a metal instead of a refrigerant gas and that metal cycles between two internal states," said Kevin O'Toole, their CTO. "Fundamentally, the difference is that metals don't leak."

When you compress the alloy, it undergoes a phase transformation and releases heat. When you decompress it, it reabsorbs heat by shifting back. This is called the electrocaloric effect.

NO GAS. NO LEAKS. NO EMISSIONS.

The engineering that makes it work

They compress and decompress strips of this metal alloy inside heat pumps. As it cycles between austenite (the high-temperature phase) and martensite (the low-temperature phase), it moves heat efficiently without any gaseous refrigerant.

The beauty is in the solid-state phase transition. Unlike boiling and condensing a liquid (which needs containment and inevitably leaks), this metal just changes its internal crystal structure while staying solid.

They're even experimenting with 3D metal printing to create bespoke alloys with enhanced heat transfer properties.

Why this rewrites HVAC engineering

Think about the implications: data centers that don't leak greenhouse gases, heat pumps that last decades without refrigerant top-ups, fridges that actually stay cold forever.

Ireland alone hosts massive data centers with huge cooling demands currently dependent on HFCs. This technology could eliminate those emissions entirely.

Exergyn partnered with Carrier Global Corporation (the HVAC giant) to scale this up. We might be looking at the end of refrigerant gases.

Sometimes the best engineering solutions come from asking "what if we just used a completely different material?"

Your next adventure?

⦁ Sr Avionics Manufacturing Engineer: Relativity Space

Wiring rocket brains so they don't short-circuit halfway to orbit.

⦁ Engineer: Clark Construction

Construction boot camp rotating fresh grads through every hard hat job before handing them the keys.

⦁ Senior Reliability Engineer: Collins Aerospace/RTX

Preventing military aerospace equipment from rage-quitting mid-mission.

Want to post a job to an audience of over 80k engineers? Click here to book a call with me to see how we can partner to help!